Talking About Prefabricated Buildings

Release Time : 2019-08-28 12:55:28Prefabricated buildings are known for their environmental protection, energy saving, and fast construction speed, so the state vigorously promotes prefabricated buildings. So, why develop prefabricated buildings? What is a prefabricated building? How are prefabricated buildings produced? Let's talk about prefabricated buildings.

Policy dividends of prefabricated buildings

In March 2017, the Ministry of Housing and Urban-Rural Development issued the "13th Five-Year Plan" Prefabricated Building Action Plan, "Prefabricated Building Demonstration City Management Measures", and "Prefabricated Building". The Measures for the Management of Industrial Bases clearly point out that by 2020, the proportion of prefabricated buildings in the country will reach more than 15% of new buildings, of which more than 20% will be in key promotion areas, more than 15% will be actively promoted in areas, and more than 10% will be encouraged to be promoted. By 2020, more than 50 prefabricated building demonstration cities, more than 200 prefabricated building industrial bases, more than 500 prefabricated building demonstration projects, and more than 30 prefabricated building science and technology innovation bases will be cultivated, so as to give full play to the leading and driving role of demonstration.

In June 2017, the Ministry of Housing and Urban-Rural Development issued three national standards, including the Technical Standards for Prefabricated Concrete Buildings, the Technical Standards for Prefabricated Steel Structure Buildings, and the Technical Standards for Prefabricated Wood Structure Buildings, were officially implemented.

In July 2017, the Department of Building Energy Conservation and Science and Technology of the Standard and Quota Department of the Ministry of Housing and Urban-Rural Development issued the "Notice on Doing a Good Job in the Training, Publicity and Implementation of a Series of Standards for Prefabricated Buildings", requiring construction departments, construction committees (planning committees), construction corps and other relevant units across the country to vigorously publicize, train, and implement prefabricated buildings in accordance with the standards.

In November 2017, the Ministry of Housing and Urban-Rural Development issued the "Letter on Identifying the First Batch of Prefabricated Building Demonstration Cities and Industrial Bases", announcing 30 prefabricated building demonstration cities (including Beijing, Shanghai, Tianjin, Shenyang, Nanjing, Hangzhou, Hefei, Zhengzhou, Chengdu, etc.), and awarding 195 units the title of "prefabricated building demonstration industrial base" to further promote the implementation of prefabricated buildings.

Why develop prefabricated buildings?

l/ Development of urbanization

After the reform and opening up, a large number of migrant workers poured into the cities, urbanization developed rapidly, the urban population surged, and it was urgent to solve the problem of population housing.

2/ Population ageing

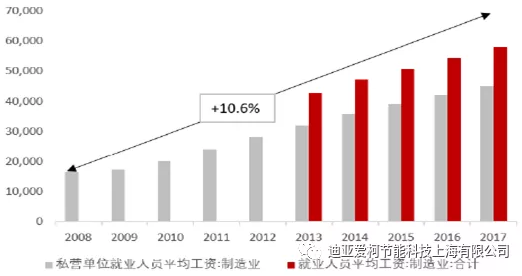

With the development of the economy, the people's living standards are improving, the problem of population aging is becoming more and more serious, the price of labor will become increasingly expensive, and the cost of labor will increase.

3/ The development of science and technology

The continuous development of modern science and technology has laid the foundation for the industrialization process of the construction industry, and the construction industry will inevitably transform from a labor-intensive industry to a technology-intensive industry.

4/ Improvement of building quality requirements

With the rise of China's comprehensive national strength, it can also be seen from the country's revision of the "Unified Standard for the Reliability Design of Building Structures" that our requirements for construction projects will only get higher and higher. Starting from the aspects of improving quality, reasonably speeding up the construction period, environmental protection and energy saving, the prefabricated building under the industrialization mode has unique advantages.

4/ Requirements for energy conservation and environmental protection concepts and green buildings

The traditional construction industry will produce a large number of environmental pollutants such as construction dust, construction noise, and construction waste. The mode of factory production and on-site assembly will greatly reduce the emission of pollutants, allocate the use of resources more reasonably, and achieve the effect of energy conservation and environmental protection.

To sum up, the development of prefabricated buildings is an important measure to promote the supply-side structural reform and the development of new urbanization, which is conducive to saving resources and energy, reducing construction pollution, improving labor productivity and quality and safety level, and is conducive to promoting the deep integration of construction industry and information industrialization, cultivating new industries and new kinetic energy, which is the only way for the development of the construction industry.

What is a prefabricated building?

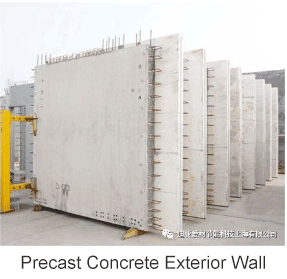

Prefabricated building is a new type of sustainable building production mode that integrates various business fields such as R&D and design, production and manufacturing, on-site assembly, etc., and realizes energy saving, environmental protection and maximization of the value of the whole cycle of building products. The term assembly was first used in the field of machinery, which refers to the process of assembling parts according to the specified technical requirements and debugging and inspection to make them qualified products. To put it simply, it is the process of assembling parts into a single unit. Applied to the field of architecture, prefabricated buildings can be simply understood as: buildings that directly assemble various parts of a building on site. The most basic components of a building, from the Shanghai Tower, the Burj Khalifa, to the two-storey building handed down from our ancestors, are nothing more than the foundation, columns, beams, floors, stairs and other main parts. In order to realize the on-site assembly of building components, the prerequisite is that these components must be produced in the factory in advance, referred to as prefabrication. Therefore, in many cases, prefabricated buildings are also called prefabricated buildings or building industrialization.

Of course, there's much more to a building than that. Beams, slabs, columns, etc., are just structural parts of the building, which are equivalent to a person's bones. A fully functional building is also inseparable from the envelope (skin); equipment, pipeline systems (blood), etc. Therefore, prefabricated buildings do not only involve the assembly of structures, but also involve many other professional assembly or coordination problems, which is a very complex and systematic project.

Production of prefabricated buildings

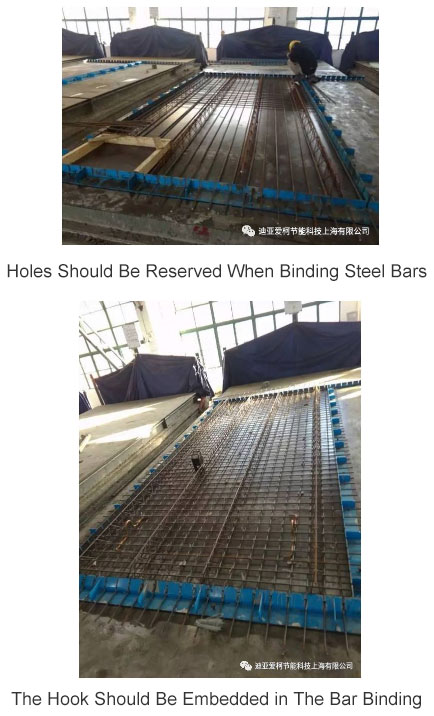

Taking prefabricated building slabs as an example, the production process is: steel mold production→ steel bar binding→ concrete pouring → demoulding

After the prefabricated components are made, they are temporarily classified and stacked in the factory, and they can be ready to be transported to the construction site for construction operations.

Epilogue

We should break the rigid thinking, get out of the traditional building model to give us the shackles, and actively cater to the national policy of developing prefabricated buildings, in the general trend of the development of prefabricated industries, in all aspects of prefabricated buildings to introduce new technologies and new methods, open up new ideas, develop green, environmentally friendly, high-quality prefabricated buildings, and usher in the spring of prefabricated buildings faster.

Shanghai ICP for 19000999-1

Shanghai ICP for 19000999-1